21 Reasons Perceptive Farmers and Ranchers Choose Steel Buildings In part one of this series on agricultural building trends, we learned both farms and farming…

Category: General Information

The Super-Sizing of U.S. Farming BIG defines the agricultural building trends today. Farms are bigger and so are tractors and other farming equipment, creating an…

Why Farmers and Ranchers Choose Pre-engineered Steel Buildings People who enjoy country living favor building green, eco-friendly structures on their rural properties. Whether their country…

Eco-Friendly Building in the Cornhuskers State Starts with Steel Pre-engineered metal buildings in Nebraska stand up to the unique challenges facing cornhuskers. Nebraska’s volatile climate…

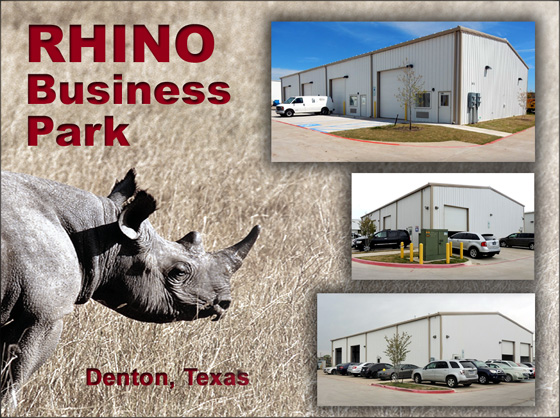

Phase 4 Completed at the Industrial Park in Denton, TX Last year we told our readers about the RHINO Business Park under construction. At that…

Building Your Own Convenience Store Business Part 1 in this series covered the basic statistics on convenience stores in the U.S. Now let’s look at…

New Ideas to Raise Revenues for a Self-Storage Operation Part 2 of this series on mini-warehouse expansion covered several traditional ways of expanding a self-storage…

How to Increase Profits for Your Self-Storage Facility There are three times a mini-warehouse business should consider expansion: 1. When the current facility reaches 85%…

Eco-Friendly Metal Buildings and Mini-Warehouses Environmentally conscious builders, developers, and investors overwhelmingly turn to pre-engineered steel buildings when planning green self storage projects. Building mini-warehouse…

The Race for Space in Our Homes and Businesses Like any other successful U.S. business, the self-storage industry began as a solution to a need:…