Eleven Ways Pre-engineered Steel Buildings Beat Other Construction Methods

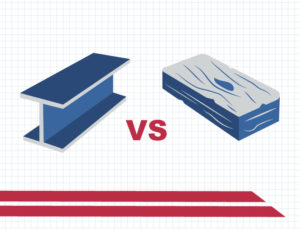

First, let’s look at how prefab metal buildings differ from traditional structures.

All conventional construction methods require skilled workers to laboriously create the building on site, piece by piece.

Carpenters measure, saw, level, assemble and nail the wood-framed structures together one stick at a time. (Hence the name, “stick-building.”)

Carpenters measure, saw, level, assemble and nail the wood-framed structures together one stick at a time. (Hence the name, “stick-building.”)

Light-gauge steel framers use the same basic process. They simply substitute steel studs for wooden ones, then assemble the framing with screw guns instead of nail guns.

A pre-engineered metal building (PEB), however, is produced in a factory. All the framing pieces ship from the factory to the construction site. They arrive ready to bolt-together quickly and easily. No muss, no fuss, no waste.

PEBs Rule Today’s Market

Prefab metal buildings currently boast a 71% market share in commercial construction in the U.S., according to Buildings Guide. Even more amazing, PEBs sweep the industrial market with a hefty 95% share.

According to Grand View Research’s 2019 report, the pre-engineered building market is continuing to expand. They predict global sales to reach $30.8 billion by 2025, up from $9.7 billion in 2017. The North American market alone should enjoy a 13.9% compound annual growth rate in the next five years.

Have you ever heard of any product so dominating its market?

Comparing Prefab Metal Buildings to Conventional Construction

So what accounts for the phenomenal success of prefab metal buildings? See for yourself. Check out the following eleven ways PEBs beat the competition:

Attractive

Forget any preconceived stereotypes. Pre-engineered metal buildings do not have to look like a steel barn. Stucco, brick, stone, cement board, and tilt-up concrete are all possible on a metal building exterior. In fact, steel framing allows the use of any conventional façade.

Moreover, rigid-frame steel buildings go up perfectly plumb— and stay that way for the lifetime of the building. You cannot expect that kind of stability with wood framing.

Strong

Surprisingly, steel-framed buildings usually weigh less than wood structures— and they certainly weight less than concrete or block buildings. So how is that possible?

Steel has the highest strength-to-weight ratio of all common building materials. Consequently, it takes far less steel to create a much stronger building.

Think of it this way: if wood was stronger and lighter than steel, we would all be tooling down the freeways in wooden cars instead of steel. I don’t see that happening, do you?

Durable

No building material lasts longer than steel. A prefabricated metal building holds it value and appearance year after year— and without the constant upkeep wood buildings require.

Simple

Prefabrication in a factory turns metal building kits into life-sized erector sets. You just bolt the building together per the instructions. There is only way for it to go together— the right way.

What could be simpler?

Safe

Steel’s inherent strength provides a sturdier, safer structure than wood framing. Steel offers additional protection from violent storms and trembling earthquakes.

Equally important, steel is non-combustible. It never ignites nor adds fuel to a structural fire. No wood structure can make that claim.

Rigid-iron prefab metal buildings also beat light-gauge steel buildings in a fire.

Consider no building fireproof— even steel. However, commercial-grade rigid steel framing holds its shape much longer than light-gauge steel framing, which can collapse without warning during a fire.

Versatile

The flexibility of the prefab metal building system is astounding. It adapts easily to virtually any size of use.

Can you even imagine a gigantic warehouse or a huge commercial aircraft hangar framed in wood? It simply wouldn’t work, would it?

Yet this same, simple steel system works equally well for small and mid-sized buildings. From your backyard workshop, to a busy grocery store, to a mega-sized online fulfillment centers, steel does it all.

Quick

Prefabricated metal buildings arrive ready to erect. The factory clearly marks each piece so assembling the frame is a snap. Consequently, a smaller construction crew is required than for more labor-intensive buildings.

Moreover, steel’s great strength means far fewer framing pieces are needed than with typical wood framing. Steel building columns are generally spaced at 25-foot intervals. However, wood studs are placed only 16-inches apart.

Expect to slash construction time by a third or more when you choose a prefabricated steel building.

Predictable

One of the great advantages of PEBs is the consistency of the framing itself. As a manufactured material, steel columns and rafters are perfectly straight and true. It is impossible to find wood studs with that sort of consistency.

Steel never shifts or changes shape with moisture variations. Wood, unfortunately, changes constantly with temperature and humidity changes. Consequently, lumber warps, twists, creeps, and sags as the building ages.

And steel never rots like wood. As an inorganic material, steel never molds or mildews. Nor will steel framing ever become a haven for termites, as a wood structure does.

Available

Although recycling and reforestation efforts have been laudable in recent years, the quality and quantity of available lumber is still a huge problem.

Today’s lumber is cut from much younger— and weaker— trees than in yesteryear. Wood builders find they need to cull out 15%-20% of a framing order. (Worse yet, they may try to cut corners and used the defective studs, leaving you with a less stable building.)

Steel is readily available. It is the most recycled material in the world today. In addition, steel is the only material that never loses any strength when recycled. No matter how many times you recycle it, steel is just as strong as when first created!

Green

Not only is steel the most recycled building material, it is also the most eco-friendly.

The high-recycled content of steel— coupled with the longer lifecycle of the structure— makes it a favorite of green building enthusiasts. At the end of the building’s usefulness, the steel framing is recycled one again, to live on as a ship, car, train— or another steel building!

Steel is too valuable to discard like wood and concrete, left to take up space in the nearest landfill.

Economical

Of course, the bottom line is this: How much does a metal building cost?

The design and manufacturing process for metal buildings is incredibly efficient. Technological advances have streamlined the process even further, making pre-engineered steel buildings the best buy for most one and two-story structures.

Even better, metal buildings are also very economical to operate. With an excellent insulation system, these structures can cut utilities in half. Steel buildings require very little maintenance, too. Plus, steel’s fire-resistant qualities earn big discounts with most insurance carriers.

Conclusion

Look again at those market figures at the first of this article.

Do you think steel could garner 71% of the commercial market and 95% of the industrial market if it was not economical, cost-efficient, and durable?

The “big guys” in building know the best building deal is steel! Follow their example.

Test Our Metal Today!

Trust RHINO Steel Building Systems for your next project. Our products and customer service make us stand out from the common herd of steel building companies. In addition, our steel buildings offer an array of bonus features— at no additional cost!

Call 940.383.9566 for information, building tips, free quotes, and the best building at the lowest price.