Which Metal Building Foundation is Right for Your Building?

A steel building foundation performs an incredibly important function. A properly designed and laid building foundation supports your structure and avoids major problems.

Basic Types of Foundations for Steel Buildings

Pre-engineered metal buildings typical use one of three foundation systems:

Pre-engineered metal buildings typical use one of three foundation systems:

- Slab

- Pier

- Perimeter wall

SLAB FOUNDATION: A concrete slab foundation is the most popular choice for metal buildings.

Basically, a concrete slab for metal buildings creates a floor for the structure while supporting the steel framing.

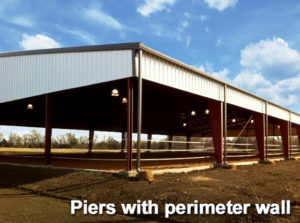

PIERS: Steel building structures requiring a dirt or gravel floor use concrete piers to support the structure. For example, livestock barns often have pier foundations.

Structures not completely enclosed— such as open-air pavilions and horseback riding arenas— also find pier foundations preferable.

Structures not completely enclosed— such as open-air pavilions and horseback riding arenas— also find pier foundations preferable.

Concrete piers are poured deep within the soil, with one pier supporting each steel column of the framing. The piers are tied together below ground to eliminate shifting.

PERIMETER WALLS: Another type of metal building foundation is the perimeter wall, also known as a perimeter footing. These steel building foundations pour around the exterior of the structure, supporting the exterior steel framing walls.

Some building applications also use perimeter walls in conjunction with a concrete slab foundation or piers.

Choosing Your Steel Building Foundation

The purpose of the structure, the style of the building, and the building’s location all determine the choice of foundation.

The purpose of the structure, the style of the building, and the building’s location all determine the choice of foundation.

The following criteria need to be included in the selection of foundations for steel buildings:

- Soil type

- Local frost lines

- Building’s weight

- Weight of equipment or vehicles to be housed in the structure

- Dimensions

- Building Reactions

- Location of anchor bolts to attach steel framing columns

Who Designs a Metal Building Foundation?

You will need to hire a local concrete engineer to design your steel building foundation. They will be best qualified to determine the specifics for using perimeter walls, piers, or a concrete slab for metal building foundations.

You will need to hire a local concrete engineer to design your steel building foundation. They will be best qualified to determine the specifics for using perimeter walls, piers, or a concrete slab for metal building foundations.

RHINO provides the anchor bolt plans and technical information your foundation engineer and contractor need to plan the perfect foundation for your steel structure. This allows your foundation to be poured and cured in advance, so construction can begin immediately when your steel framing arrives.

TIP: If soil conditions are poor, you may find it less expensive to bring in a better grade of dirt than to pour a deeper foundation for a larger steel structure. Discuss this possibility with your contractor.

RHINO’s Formed Base Trim and Base Girts

Most steel building companies require concrete slabs or perimeter walls include a notch in the concrete to hold exterior sheeting. The concrete contractor creates the notch by placing 2 x 2 boards around the edge of the concrete.

Most steel building companies require concrete slabs or perimeter walls include a notch in the concrete to hold exterior sheeting. The concrete contractor creates the notch by placing 2 x 2 boards around the edge of the concrete.

Unfortunately, the notch tends to hold pockets of water, which rusts the wall sheathing over time.

Fortunately, RHINO supplies formed base trim. Formed base trim eliminates the need for notching the concrete. It allows the exterior wall sheathing to rest on a metal ledge on the outside edge of the foundation, avoiding rust problems.

RHINO also includes foam closure strips shaped to match the exterior steel panels. Using this technique furnishes a tighter seal between the building and the foundation. It also looks more professional when completed.

In addition, using formed base trim also saves an average of $300 on your foundation costs over the notched concrete method.

Where the structure calls for piers only— without the perimeter walls— RHINO substitutes a base girt for the base angle. Made of heavier steel, the base girt supports the weight of the structure between the piers.

Conclusion

Trust RHINO Steel Building Systems for top quality steel framing with value-added features.

Trust your local concrete engineer and concrete contractor to use the information supplied by RHINO to design and create the strongest foundation for your RHINO structure.

Learn More about Foundations for Steel Buildings

Discover The RHINO Difference in steel buildings.

Contact RHINO today for more information about metal building foundation options. You can reach RHINO by calling 940.383.9566.

(Updated 5-5-2021. Originally published 3-20-2015.)