What Purpose do Purlins Serve on a Steel Building?

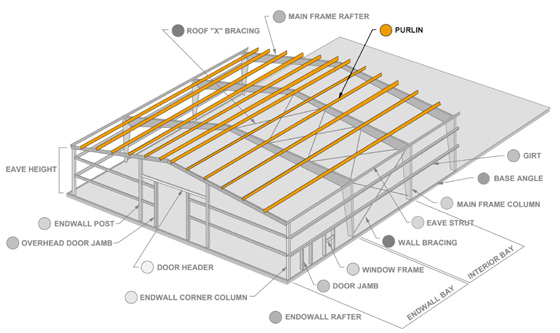

What are purlins on a roof? Let’s get down to the basics of metal building roof purlins. Purlins are an important component in a pre-engineered steel structural kit. These structural supports run perpendicular across the rafter beams.

Also known as “sheeting rails,” purlins create the roofing members of the secondary framing of a steel building.

The Purpose of Purlins

Metal building roof purlins provide three structural functions:

Metal building roof purlins provide three structural functions:

- First, the purlins support the roof.

- Secondly, purlins tie the rafters together, stabilizing and strengthening the structure’s rigid framing.

- Thirdly, purlins add additional support between the spans of the individual framing bays.

As an added bonus, metal roof purlins increase the structure’s resistance to strong winds.

Steel Building vs. Wood Building Roofing

Wood framing employs decking to tie roof trusses together and support the roof. Decking is heavy and expensive. It is also time-consuming to install, driving up labor costs.

Steel building purlins eliminate the need for oriented strand board (OSB) or plywood decking. Consequently, a metal building system saves money on both building material and labor.

Types of Purlins

In general, metal roof purlins come in two varieties: C-purlins and Z-purlins. These purlin styles get their names from their shapes. When looking at the ends of the rails, the purlins shapes look like the letter “C” or the letter “Z.”

In general, metal roof purlins come in two varieties: C-purlins and Z-purlins. These purlin styles get their names from their shapes. When looking at the ends of the rails, the purlins shapes look like the letter “C” or the letter “Z.”

The eave purlin marks the first purlin at the wall connection.

Spacing for Purlins

On a standard load, most designs call for purlin placement at five-foot intervals. However, engineering determines the optimal roof purlin spacing. The heavier the expected load is, the shorter the distance between the purlins.

RHINO Metal Building Purlins and Options

Traditionally, RHINO steel buildings use 8” to 10” primed red-iron C-purlins and Z-purlins.

If your design or local building codes demand extreme spans or snow loads, taller purlins may be required. Taller purlins also allow room for increased insulation.

For coastal climates where high-humidity or salt corrosion poses problems, RHINO offers optional galvanized purlins, if desired.

How RHINO Purlins Are Better

Some steel building companies provide purlin connections that butt flush against each other on the rafter.

However, at RHINO, we design our purlin systems for maximum strength.

The greater the amount of overlap between connecting purlins, the stronger the connection will be. Consequently, all RHINO purlins overlap by design. The amount of lapping increases as the load increases.

Moreover, RHINO rafters have factory-welded clips already installed for attaching purlins. Pre-welded clips simplify construction and speed up the purlin framing process.

Call RHINO today at 940.383.9566 to learn more about the cost-effective RHINO Difference of low-rise construction. Our experts are standing by to take your call now to answer questions about our metal building roof purlins.