Defining a Pre-engineered Metal Building System

A steel framed building system creates an incredibly strong, long-lasting, affordable structure.

The flexibility of pre-engineered steel buildings makes them the ideal building solution for most low-rise agricultural, aviation, commercial, industrial, recreational, storage, and worship structures.

What exactly is a Steel Framed Building System?

A metal building system is exactly that— a system.

A metal building system is exactly that— a system.

Sophisticated steel structural software is used to design and engineer the structure.

The software then creates detailed drawings for the fabrication of each framing component of the prefabricated metal building.

Factory-trained professionals manufacture each piece of the framing to these exacting specifications. Fabricators cut, shape, weld, drill, punch, paint, and mark each framing piece for quick identification.

Our steel framing systems ship to the job site, ready to assemble.

Pre-engineered Steel Buildings: Like Life-Sized Erector Sets

The steel building framing erects in a systematic, logical order:

The steel building framing erects in a systematic, logical order:

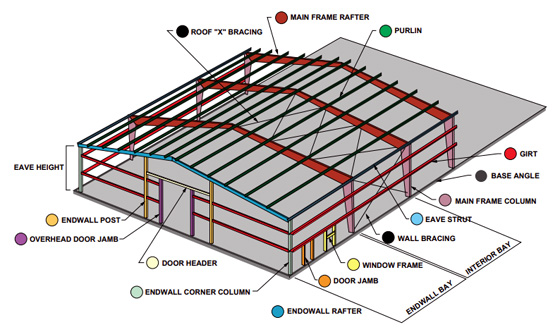

- Factory-produced steel “red-iron” column and rafter beams bolt together with heavy-duty steel bolts and nuts, forming a single frame.

- These frames bolt to the foundation, creating a “bay”— the area between two frames.

- Steel girts are attached to the sides of the columns for lateral support.

- Steel purlins connect the frames across the roof.

- Typically, corrosion-resistant Galvalume® steel panels screw to the roof and exterior walls forming the “skin” of the prefabricated metal building. However, a RHINO metal building system may also be finished with block, brick, glass, stucco, stone, tilt-up concrete, or any other traditional exterior finish.

In addition, all RHINO pre-engineered steel buildings include an anchor bolt diagram and three full sets of plans stamped by an engineer licensed for that state, plus a Letter of Certification to expedite permitting.

What other building system is guaranteed to meet or exceed all current building codes for the lifetime of the structure? You will certainly not get that sort of guarantee from your wood builder or a weld-up steel builder!

Conclusion: RHINO’s Metal Building System ROCKS

Nothing could be stronger or simpler to construct than a RHINO steel framed building.

Call the Steel Building Framing Experts at RHINO

Contact RHINO Steel Building Systems now for more information about our commercial-grade steel building framing.

Contact RHINO Steel Building Systems now for more information about our commercial-grade steel building framing.

You can trust our experienced metal building specialists to answer your every building question. They can also provide valuable professional advice for streamlining your prefabricated metal building project.

Free quotes are also available.

The RHINO hotline number is 940.383.9566.

(Updated 8-11-2021. Originally published 3-29-2016.)