The Little Part that Makes a Big Difference

In a recent post on tools, we discussed using a high-performance screw gun with a clutch to install metal building screws. Now let’s look at why that is so important.

Start with High-Quality Metal Building Screws

Inferior steel buildings with cut-rate screws tend to leak. Not only does a leak make a soggy mess inside a building, but cheaply made screws rust and discolor the exterior of a metal building, too. Who needs that hassle?

Inferior steel buildings with cut-rate screws tend to leak. Not only does a leak make a soggy mess inside a building, but cheaply made screws rust and discolor the exterior of a metal building, too. Who needs that hassle?

RHINO Steel Building Systems uses every possible method to keep their pre-engineered metal buildings watertight. Our steel building packages include many waterproofing features designed to keep our metal buildings snug and dry for decades— at no additional cost to the customer.

However, even the best materials, fasteners and self-tapping metal building screws will not perform well if they are installed incorrectly.

Building it Right to Make It Watertight

RHINO’s die-cast zinc aluminum metal building screws deliver high torsional strength. The efficient self-drilling tip speeds up construction. These metal siding screws come with a lifetime warranty against red rust forming on the zinc head.

RHINO’s top-of-the line sheathing screws even come in colors to match the steel panels, for a more professional finish!

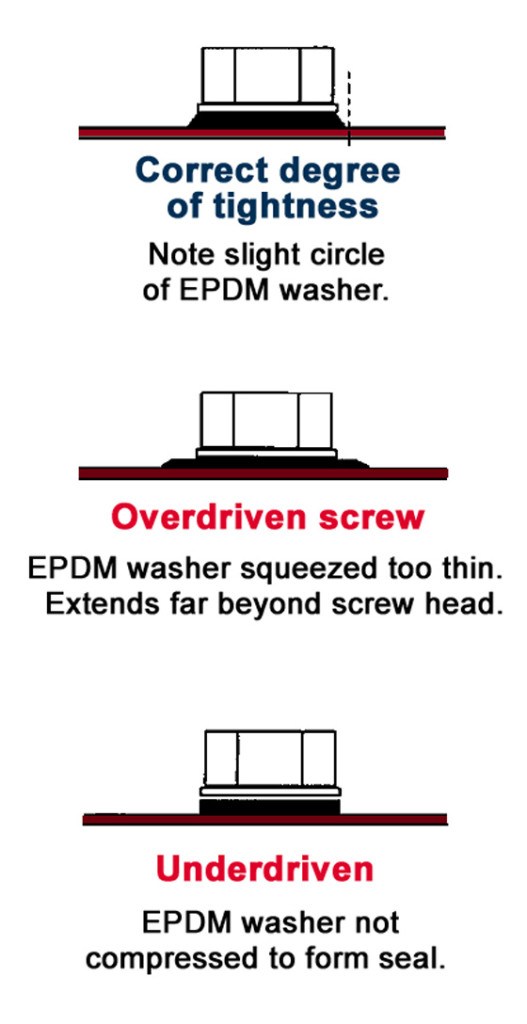

Each self-drilling metal building screw includes a durable EPDM (Ethylene Propylene Diene Monomer) washer, which is resistant to ozone and ultraviolet light damage. The EPDM washers provide an excellent waterproof seal— even under the most severe weather conditions— if properly installed.

The trick is not to overdrive or underdrive the screws. If the screw is not tightened enough, moisture leaks around the washer. An overtightened screw squishes the washer too thin, which can also result in leaks.

The trick is not to overdrive or underdrive the screws. If the screw is not tightened enough, moisture leaks around the washer. An overtightened screw squishes the washer too thin, which can also result in leaks.

That is why a good screw gun with a clutch is so important. The adjustable nose allows the user to set the countersink to exactly the right depth.

The RHINO Installation Manual recommends a screw gun with a 1700-2000 RPM for the self-drilling screws. A screw gun with 500-600 RPM works best for self-tapping screws.

Important Tip: Replace worn sockets immediately if they cause the screw to wobble during installation. Crookedly driven screws can cause water leaks.

Test Our Metal!

Call RHINO at 940.383.9566 today. Speak to a metal building specialist. Ask questions about metal building screws, learn more about our company and our products, or get a quick quote. We are here to serve you!