RHINO Steel Building Systems has been in business since 1998. Our management and sales consultants are experienced in all phases of construction of prefabricated steel buildings. RHINO’s deliveries include thousands of buildings to all 50 states, Canada, and Mexico. We invite you to check the Better Business Bureau and compare our A+ rating against the competition. In the last year, satisfied repeat clients, or those referred to RHINO by our customers, generated 30% of our business. We believe that says volumes about the quality of our products and our service.

RHINO does not have its own construction crews. However, we know many independent erectors who can construct our buildings for you. We can recommend commercial, storage, or farm building contractors in your area for steel building erection.

A large percentage of our buyers erect their own RHINO metal building. Our prefabricated steel building kits arrive with the steel components cut, welded, and drilled for easy bolt-together installation. It’s basically a big kid’s erector set.

RHINO metal building specialists have years of steel building erection experience. Over the years, we have encountered almost every building situation conceivable. Therefore, we are well-equipped to answer your every question and handle your every need. If you have a question during the construction process, we are just a phone call away.

The average time to erect the framing for a 40′ x 60′ x 14′ building with a three-man crew is about five days. A 60′ x 100′ x 16′ normally takes about seven days to erect.

Besides the normal everyday tools, you will require lifting equipment to raise the columns and rafters.

For example, a typical agricultural building has a 16′ tall column, which weighs 200-250 pounds; the rafter would weigh 500-700 pounds for a 60′-wide rafter. A rented forklift, track loader, or a front-end loader will work if it reaches your height requirements.

Screw guns will be required to install the self-drilling screws. The guns should have an adjustable clutch that will disengage the driver, so as not to strip out the neoprene washer on the screws as it tightens. The cost of a new screw gun from Dewalt or Black and Decker is around $130.

We determine your shipping costs by the overall weight, number of trucks needed, and the driving distance from the plant that is nearest to your location. RHINO offers multiple shipping points all across the country to keep the overall shipping costs to a minimum.

RHINO standard steel building kits include these premium features at no extra cost:

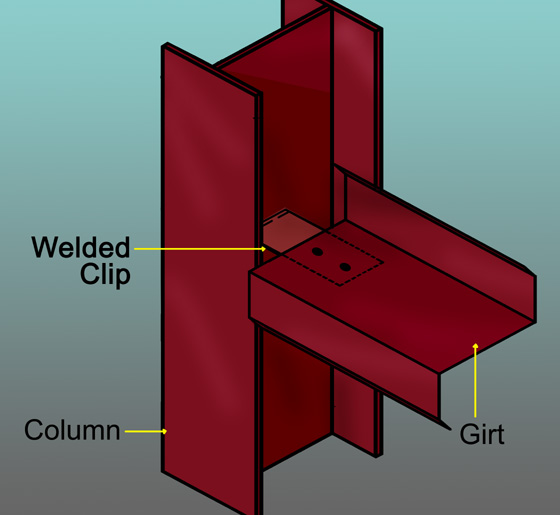

- Prefab steel framing, factory-formed and identified for easy job site assembly, with clips already welded to frames for girt and purlin attachment

- Steel building trim

- High-strength bolts with nuts and cast zinc self-drilling screws

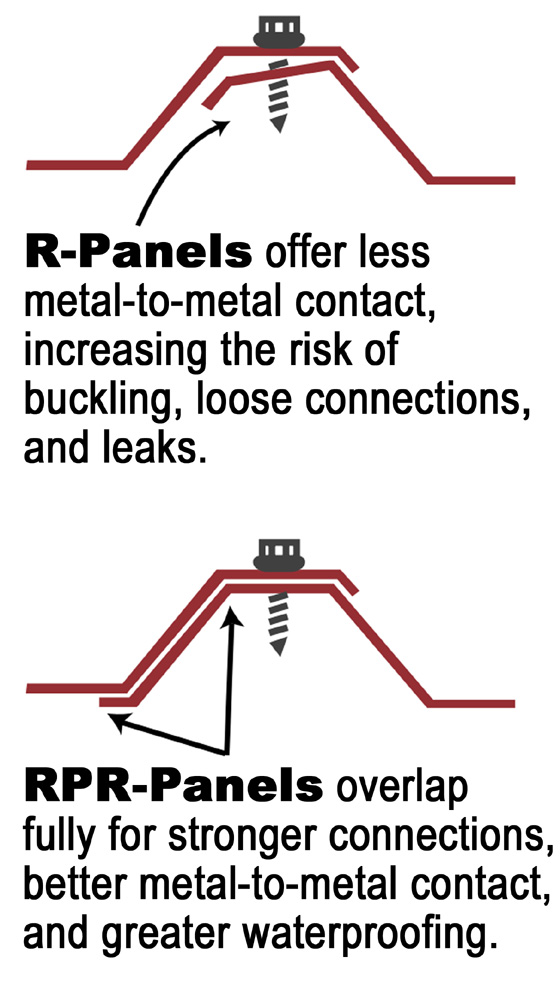

- 26-gauge high-tensile PBR steel color roof and wall panels and color trim

- Closures and mastic for the base, top of the wall panel, and underneath the roof at the eave to completely seal the building

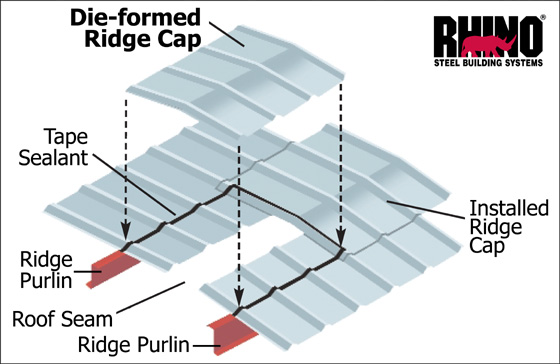

- Die-formed ridge caps conforming to the standard roof panels for a waterproof seal

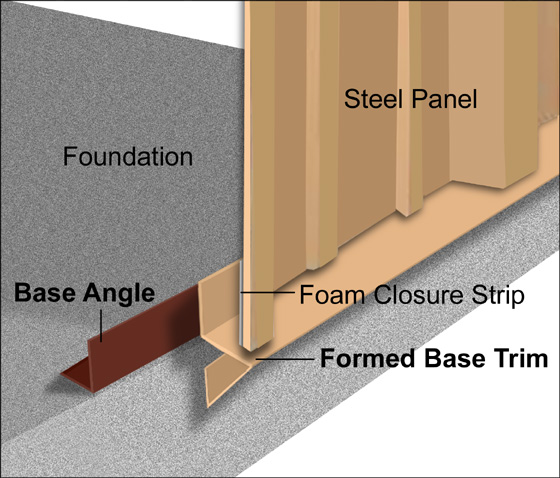

- Steel formed base trim to eliminate rust

- A framed opening for an overhead door up to 30′ wide

- Base trim and cover trim for overhead doors

- Cover trim for all doors and windows

- 3 sets of Engineer-Stamped Prints with a Letter of Certification

- Anchor bolt plan

- 49-page Installation Manual and Construction DVD

- Bill of Lading listing all parts purchased

Anchor bolts secure your steel building frames to the slab foundation. RHINO does not furnish anchor bolts, but they are easily obtained locally.

Simply put, we include more high-quality standard items in our kits than our competitors provide — and we give our customers unbeatable service.

Unlike most other steel building companies, we provide PBR roof and wall panels, zinc cast self-drilling screws with Galvalume® panels, standard closures, overlapping purlins, and a 25-year written warranty for color panels.

In addition, our structures include clips already welded to frames for the attachments of girts and purlins (making the erection process easier and faster), plus standard base trim and cover trim for all overhead door framed openings. Moreover, all RHINO buildings ship from AISC certified manufacturing plants.

We are determined to offer the best customer service in the industry. Our sales team has years of experience in the metal building industry.

RHINO has earned an A+ rating with the Better Business Bureau. Satisfied repeat clients — and those referred to RHINO by happy customers — generated 30% of our business in the last twelve months.

We deliver the highest quality metal building product possible and provide the most helpful and friendly service in the industry.

The building comes with a complete anchor bolt design providing the building dimensions and reactions (or KIPS). From this information, an engineer (hired by the customer) designs the proper foundation.

You can build a RHINO structure on piers or a perimeter foundation, with or without a concrete slab. If a slab is poured, it is normally poured at the same time as the perimeter foundation.

For example, some farm building plans only require piers. When only piers are used, we delete the base angle and use a base girt. The base girt is larger and of thicker metal. It will support the sidewall sheathing without the use of a concrete foundation.

The advantage of perimeter foundations is the way the building is sealed. A closure strip, exactly fitting the corrugation of the panels, inserts between the bottom of the wall panel and the base angle around the entire perimeter. This seals the building in a way that is unmatched by a base girt or by dirt pushed up against it, as is sometimes used on farm buildings.

RHINO sells prefabricated steel buildings with components manufactured in an AISC (American Institute of Steel Construction) certified plant. All steel building frames and other materials for a complete structure are delivered to the customer’s job site.

Each building is designed to meet the wind, snow, seismic, and local building codes of the county in which the building will be constructed. All metal buildings meet or exceed the recommendations of the MBMA (Metal Building Manufacturers Association).

You will receive three sets of engineer-stamped plans, a Letter of Certification, and a 49-page Installation Manual and Construction Video with your structure.

A Bill of Lading listing all parts arrives with the order. We suggest that you check everything off the list (one by one) as you offload, until you have accounted for all materials. Report any missing parts immediately to RHINO. With RHINO’s prefab steel buildings, all framing pieces are cut, welded, drilled, and marked for easy job site assembly. The framing system is designed to go together only one way…the right way.

RHINO Steel Building Systems offers two basic insulation choices:

RHINO’s basic fiberglass insulation (from 3″ to 8″ thick) yields R-10 to R-30 ratings. This reinforced back of this insulation eliminates the need for chicken wire supports, saving both time and money, while creating a more attractive interior.

The ultimate insulation system is our RHINO Pro-Value Insulation Package. This system includes R-19 to R-30 fiberglass insulation for walls and R-20 to R-40 insulation for the roof. The Pro-Value system also includes steel retainer straps, a fabric barrier (which is 300% stronger than plain vinyl facing used by our competitors), uncompressed insulation for full energy efficient effectiveness, and a foam thermal break. The Pro-Value system slashes energy bills as much as 50%.

Many farm-building contractors, commercial fabricators, and do-it-yourselfers appreciate the convenience of having the insulation materials and other options delivered with the metal framing package.

Delivery time varies. Speak to a RHINO steel building specialist for more details. With multiple shipping locations all across the nation, RHINO steel building customers save big on delivery costs, too.

Expert advice and help is where RHINO shines the brightest. Whether you require a farm building, aircraft hangar, commercial building, agricultural metal building, manufacturing plant, industrial building, a simple storage building, or any other type of metal-framed structure, RHINO has got you covered. Our experienced and knowledgeable staff members are well equipped to help you decide the size, framing type, and amenities you’ll need, plus provide any other technical assistance you require.

In addition, RHINO’s online design tool helps you visualize the building you desire. You can determine the size and colors of your structure, as well as choose opening and door sizes and locations.

Each RHINO building is customized, prefabricated, and manufactured individually for your unique requirements and for your specific location.

RHINO offers various types of doors for your steel building. We recommend purchasing windows locally.

Framed openings for the doors and windows are factory-located in your design at the specific location you choose. This saves time and labor in the erection process.

We design larger openings to accommodate virtually any size door, including large bifold doors or slide doors for aircraft hangars or specialized farm building plans. RHINO metal buildings provide more flexibility and options.

Other accessories available to be shipped with your RHINO building order include skylights (which match the panel profile to your roof panel), wall lights, gutters and downspouts, canopy kits, mezzanines, and overhead doors. You may also order interior panels to provide a true “finished out” look to your building. Many farm buildings and other rural structure require ventilation units. RHINO offers two types of standard vents.