Energy Efficient Building Starts with Green Metal Buildings

A pre-engineered steel building creates a tighter, leak-resistant building envelope. Therefore, RHINO’s green metal buildings produce substantially lower electricity bills.

The Envelope, Please…

Basically, the building envelope is the part of the structure separating indoors from outdoors. The envelope includes the roof, outside walls, and foundation.

Basically, the building envelope is the part of the structure separating indoors from outdoors. The envelope includes the roof, outside walls, and foundation.

The goal is to build a close-fitting building thermal envelope, free of air leaks and drafts.

However, to be a truly energy efficient building, the structure must also remain tight throughout the building’s lifetime.

In addition, an energy efficient building needs to shed water effectively— and dry quickly— to avoid rot and mold.

Sealing the Building Envelope and Wood Construction

Wood-framed buildings rarely go up completely straight or square. They can’t, because they start with imperfect lumber.

Also, as an organic material, wood changes shape as its moisture content varies with changing humidity.

Consequently, lumber bends and twists.

After construction, wood framing members continue to move with fluctuating humidity. Builders call this process “creep.” Nails and staples start to work out. Long spans across the roof or over garage doors sag. Windows and doors fail to close properly.

Over time, as the structure loosens and energy stealing drafts develop.

Sealing the Building Envelope and Steel Construction

Manufactured to precise specifications in quality-controlled factories, steel framing components are straight and rigid— and remain so throughout the life-cycle of the structure.

Manufactured to precise specifications in quality-controlled factories, steel framing components are straight and rigid— and remain so throughout the life-cycle of the structure.

In addition, the bolts and screws connecting the framing do not move or come loose over time.

Also, there is no warping, splitting, or creeping with a steel building, as there is with wooden structures.

Therefore, steel framing goes up straight and square. That’s why a RHINO steel structure stays snug, draft free, and energy efficient throughout its lifetime.

To Build It Right, Build It Tight with RHINO Green Metal Buildings

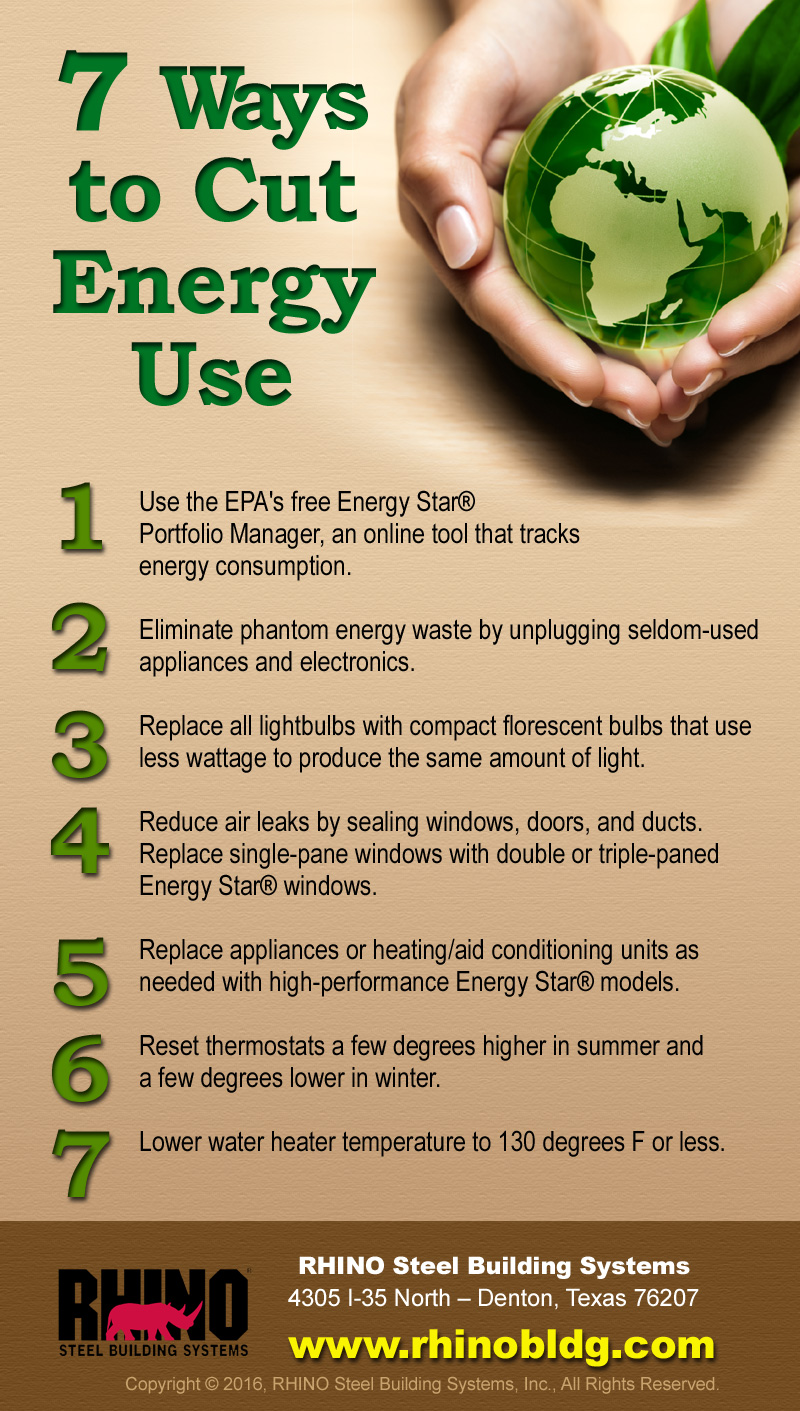

Selecting a strong, durable green building is the first step in constructing energy efficient buildings. The next step is to choose energy saving products and options to enhance the savings.

RHINO’s green buildings resist air and water leaks, mold and mildew problems, and aging much better than traditional wood construction.

Conclusion

RHINO’s metal buildings create an extremely tight-fitting, energy efficient building envelope.

Lower Electricity Bills with RHINO Green Buildings

Make the green building choice that is right for the planet— and your pocketbook. Build with RHINO.

Make the green building choice that is right for the planet— and your pocketbook. Build with RHINO.

Our optional Pro-Value insulation system typically cuts heating and cooling bills in half.

Call today for a free steel building quote on your next project— or for more information on an energy efficient building from RHINO Steel Building Systems.

You may speak to a RHINO metal building expert by calling 940.383.9566.

(Updated 12-29-2020. Originally published 4-24-2015.)