Less Hassles and Headaches with Steel Building Systems Pre-engineered metal buildings distill the building process to its simplest form. Steel building systems by design eliminate…

Category: Steel Framing 101

Using Pre-engineered Metal Building Systems to Build Metal Homes Did you know many people choose pre-engineered steel building systems to build their own steel homes?…

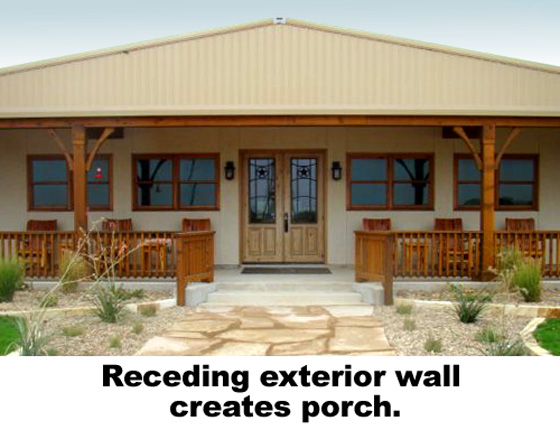

Receding an Exterior Wall Changes the Look of Metal Buildings In Part 4 of our series on “Steel Buildings: Think Outside the Box” we covered…

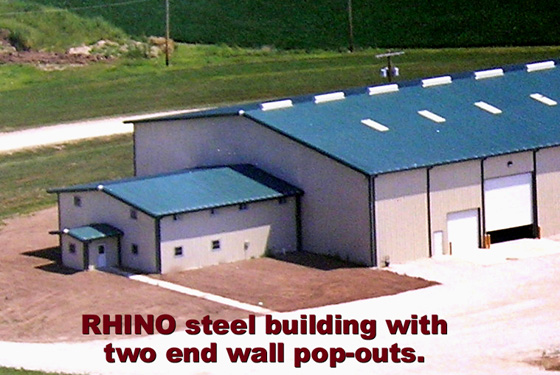

Adding Pizzazz to Metal Buildings with “Pop-Out” Framing The most economical shape for pre-engineered steel buildings remains the basic rectangle. While practical for most industrial,…

Customizing the Exteriors of Pre-engineered Metal Buildings Steel buildings do not have to look like steel buildings. There are many ways to enhance the exterior…

Roofline Extensions Add Flair to Pre-engineered Metal Buildings In part one of this series on steel buildings, we discussed changing the roof pitch and gable…

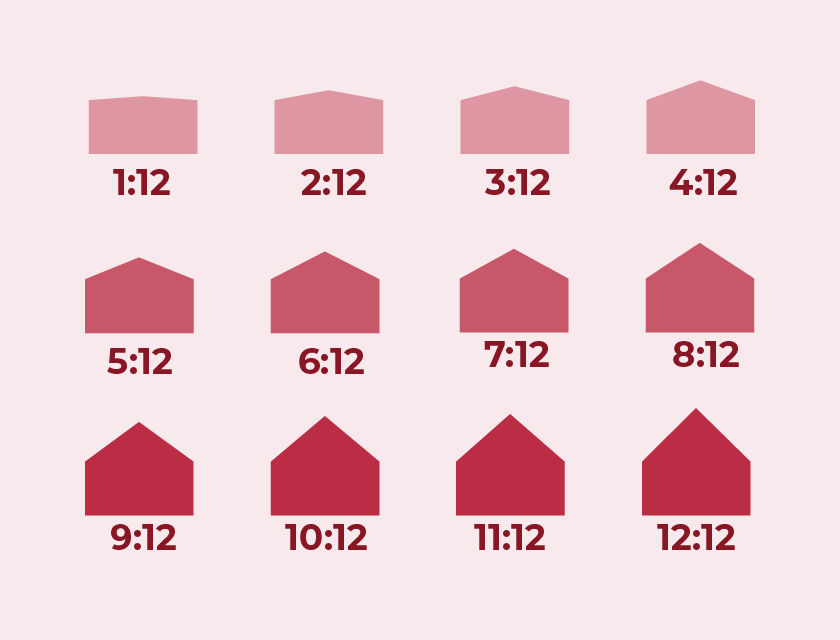

Adding Personality to a Metal Building by Changing the Roofline In pre-engineered steel buildings, nothing is more affordable than a basic box. Most agricultural, aviation,…

GOOD METAL BUILDING VENTILATION CREATES COMFORT AND EXTENDS BUILDING LIFE Never underestimate the importance of airflow in metal buildings. As discussed in part 1, adequate…

The Importance of Ventilation in Steel Buildings Providing adequate airflow in a metal building affects both the comfort level inside and the durability of the…

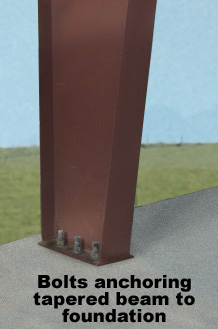

The Importance of Steel Building Foundation Connections Steel anchor bolts secure a pre-engineered metal building to the foundation. A pre-engineered steel building is only as…