Don’t Jump the Gun on Pouring the Slab!

It is tragic how many times people make the costly blunder of pouring their metal building foundation too soon.

The uninitiated think, Well pouring a slab is simple, right? I’ll just get that part of the project all finished up, then call and order a steel building to fit my slab. That is the best way, right?

WRONG!

Fundamentals Before Foundations

Pre-engineered steel building foundations are complex. The structure and the foundation work together to create the strongest possible structure. If either is compromised, the entire structure is less stable.

First, never begin any construction project before getting a building permit.

Second, consider the following things affecting the performance of a metal building foundation design:

- SOIL: What are the soil conditions where you plan to build? Is it rocky? Does the dirt have high clay content? Poor soil conditions can allow any building to sink or shift, regardless of the quality of the foundation. Sometimes it is more economical to bring in a better type of soil than to try to adjust the concrete to compensate for the poor dirt. Ask your local building department for a soil map of your area.

- FROST: The maximum depth at which the ground can freeze is called the frost line. The frost line directly affects the metal building foundation. In Canada, for example, the frost line could be 48”, while in south Texas it might be as little as 6”. Your building department or local concrete contractor will know the frost depth for your location so you can better understand how to build your foundation.

- WEIGHT: How much will the entire building and its contents weigh? If you do not have that answer yet, you certainly are not ready to pour your foundation!

Type of Metal Building System

Not all steel buildings systems are alike. Differences in the pre-engineered metal building methods also require adjustment, which you should keep in mind when deciding how to build your foundation. For example, in some systems the outside steel panels rest directly on the foundation in a channel formed when the concrete is poured.

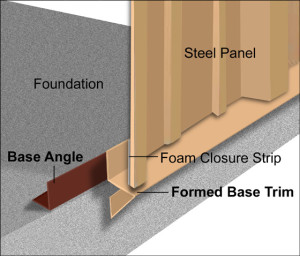

On the other hand, RHINO steel buildings include a formed base trim. No concrete notch needs to be formed on the foundation. The outside panels rest on a steel plate just outside the foundation edge, eliminating water corrosion. Consequently, the slab dimensions are different between the two methods.

Don’t Forget the Anchor Bolts!

Prefabricated steel buildings attach to the foundation with high-strength j-bolts. These bolts are embedded in the concrete when the foundation is poured for maximum strength. Pouring the foundation without the j-bolts leaves no way to attach the steel framing to the slab.

Precise anchor bolt placement is critical to a successful steel building. Check and recheck for exact alignment before the concrete dries.

Even after you receive your anchor bolt plan from the metal building company, do not rush out and start building your forms until you receive complete engineering specifications for the concrete contractor. Then— and only then— are you ready to start preparing for the foundation.

Haste Makes Waste on Foundations!

A concrete engineer bases the size, content and design of your metal building foundation on these and other factors. Without complete information, you cannot expect to create the firm foundation your steel building requires.

If you have further question about RHINO Steel Building Systems or metal building foundation designs, please call RHINO 940.383.9566 today.

Over the years, our experienced steel building advisers have successfully led thousands of customers through the steel building process. They will happily answer all your questions, supply more information, and offer you a quote on your next building project.