Steel All-Purpose Construction Buildings

Pre-engineered steel framing has a unique advantage over other building options — steel’s all-purpose building system allows it to fit any low-rise construction project, no matter the end use.

Steel buildings’ all-purpose construction is easy to erect and comes ready to build, making it extremely cost-effective. Operating a steel building is also less expensive than operating other traditional building systems. From a backyard workshop to church sanctuary to a massive distribution center or any other building need, a pre-engineered metal all-purpose building can do it all.

Specifically Designed

Specifically Designed

Although steel buildings are all-purpose constructions, there are no cookie-cutter steel buildings. Designed exactly to the customer’s specifications, every PEMB order meets or exceeds all current local building codes for that location. Today’s innovative, computer-aided design programs create prefab metal building designs easily, economically, and efficiently. Once the customer approves the plans, an engineer (specifically licensed for that state) sends a Letter of Certification to accelerate the permitting process on all-purpose constructions.

Faster Construction with RHINO

The superior strength of steel makes for simpler all-purpose construction, with far fewer framing pieces required for a much stronger structure. Since all the parts are prefabricated at a factory, the framing kit arrives ready to assemble. Most builders find a PEMB slashes construction time by 33%, saving both time and money.

RHINO’s Precision Fabrication

Next in the process, the computer program generates detailed, all-purpose construction plans for every piece of the framing package. Sent to the fabrication plant nearest the job site, these drawings guide fabricators to produce the state-of-the-art framing. Every piece is cut, welded, and drilled to the exact measurements indicated for each all-purpose building. Industry standards and tolerances are tight, and the quality-control department double checks the manufactured elements for accuracy. Once accepted, the steel framing pieces receive a coating of corrosion-resistant paint. Before shipping, fabricators mark each part for easy identification.

Floor Plan Freedom with All-Purpose Buildings

Other building materials lack the strength of rigid-frame steel while still allowing for all-purpose construction. Lumber and other structural systems necessitate walls at strategic locations to carry the roof’s weight. Load-bearing walls limit floor plan options at the time of construction and interfere with later remodeling choices.

Other building materials lack the strength of rigid-frame steel while still allowing for all-purpose construction. Lumber and other structural systems necessitate walls at strategic locations to carry the roof’s weight. Load-bearing walls limit floor plan options at the time of construction and interfere with later remodeling choices.

The commercial-grade steel used in an all-purpose building system supports the roof with the exterior columns. Pre-engineered metal buildings need no intrusive load-bearing interior walls or support columns.

A completely open PEMB offers up to 300-foot-wide clear span structures. With the addition of one center column, PEMB 480-foot-wide buildings are possible — three times the width of an NFL football field!

As an all-purpose building system, PEMBs can deliver sky-high elevations. Customers choose eaves up to 40-foot in height, and even taller buildings are possible with additional engineering.

Rigid-frame steel buildings can be any length imaginable, and a steel all-purpose building makes later expansion simple, especially in length.

Steel Buildings’ Facade Freedom

Do you think all metal buildings look like barns? No way! Many of the businesses you frequent hide a steel skeleton without you ever knowing it.

There are no limits to the exterior finishes available with today’s all-purpose buildings. Complete your structure in brick, colorful steel panels, decorative block, EIFS glass, hardy board, stucco, stone, tilt-up concrete, wood, or any combination of these treatments. You can also customize your PEMB further with canopies, gutters systems, energy-saving insulation, mezzanines, skylights and wall lights, and all types of doors and windows.

All-purpose construction allows any type of foundation to be used, including perimeter footing, pier-and beam, or concrete slab.

Sustainable System

Environmentally conscious builders rely on all-purpose construction. As the most recycled material on earth, steel tops the list of green building materials. Moreover, steel is the only material whose strength is undiminished by repeated recycling. The U.S. Green Building Council states: “Steel as a primary structural building material, with its inherently recyclable nature and its efficiency of assembly, is the logical and responsible choice for Green Building.”

A Truly All Purpose Building System

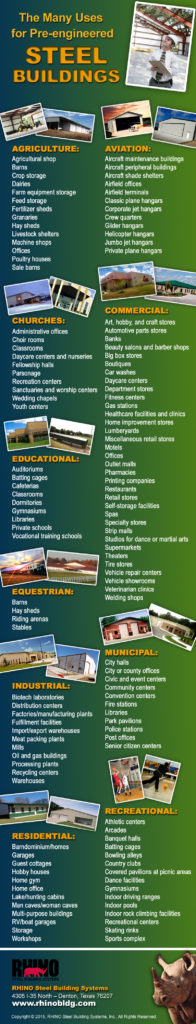

Perceptive buyers choose PEMBs for every application imaginable:

- Aircraft Hangars and Support Structures

- Automotive, Mechanic, and Welding Businesses

- Barns, Sheds, and Other Farm and Ranch Buildings

- Church and Worship Sanctuaries and Other Structures

- Distribution Centers, Mega-Warehouses, Warehouses

- Industrial and Manufacturing Structures

- Medical Clinics and Office Buildings

- Personal Storage, Recreational Vehicle Garages, Hobby Buildings, and Workshops

- Restaurants

- Retail and Commercial Structures

- Self-Storage Businesses

- Sports and Recreational Centers

Limited Only by Your Imagination

RHINO’s all-purpose building system offers the finest product and building options in the industry.

We believe in providing first class service before, during, and after the sale. In fact, repeat buyers and referrals make up 30% of RHINO sales in the past 12 months. This speaks volumes about the quality of RHINO’s customer service.

For durability, adaptability, and economy of construction, a RHINO steel building offers the ultimate choice for every low-rise construction project.

Join the herd of happy customers hooked on RHINO. Call 940.383.9566 today for ideas, information, and a free quote on your next all-purpose building project.